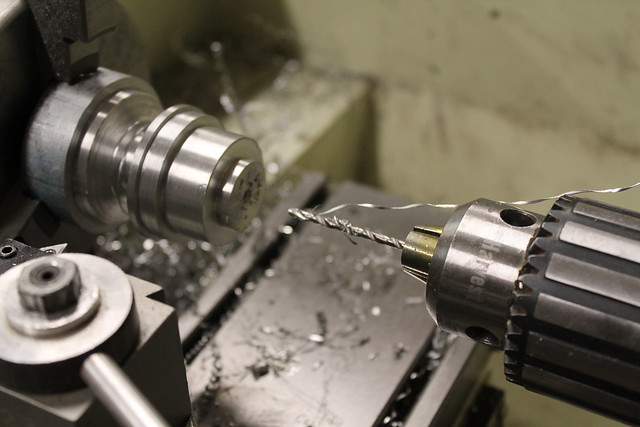

- The Mechanic: Machine Shop Blog Motorcycle Mechanic Blog Automotive Mechanic Blog. Drilling a Hole Using the Lathe. 3/24/2011 0 Comments. 0 Comments Lathe: Work Centering. See the Reading Materials (machine shop) section for a downloadable file about drill press operation. 0 Comments Technical Drawing.

- It is worth drilling a small hole even when using a center cutting end mill. The cutting speed at the center of the hole is zero, and the end mill does not have a chisel edge to open up the hole like the drill does. End mills can plunge like you did there, but they don't like it. They can also spin in the drill chuck.

- 3/4-inch holes: 248 Likes: If your priority is drilling holes, especially large ones, then the industrial-duty Bosch is a great choice. It’s heavy and it’s long, weighing nearly 5 pounds.

Fanuc G87 Side Drilling Canned Cycle. G87 Side drilling cycle is used to drill on the component diameter/side using driven tools. Read complete tutorial G87 Side drilling cycle. Fanuc G87 Side Drilling Example. 3 HOLES SPACED 120º. O0021 G21; G10 P0 X0 Z-100; N8 G28 U0. T808 (RADIAL 4MM DIA DRILL) M5 M45 G28 H0 G97 S3500 M3 G0 G80 G98 X122.Z-15. Drilling holes is a common operation in the airframe repair shop. Once the fundamentals of drills and their uses are learned, drilling holes for rivets and bolts on light metal is not difficult. Pneumatic drill motors are recommended for use on repairs around flammable materials. When using the portable power drill, hold it firmly with both hands. Wobbles or slightly bent drill bit causes.

Are you keen on getting to know more about the right options for drilling holes in metal? If the answer is yes, you can choose almost any type of general-purpose twist bit will be able to do a decent job. They will work well with different types of materials including wood, plastic and other metals. It will also be suitable for many types of thin sheet metal solutions and also thick sheet metals.

There are some twist bits which are made from HSS or high speed steel. Hence you have many options to choose from as far as types of drill bits are concerned. However, while it is quite possible to drill through many metals there are a few important points to be considered when it comes to using these drill bits and other such things.

Protect Your Eyes

While you might be keen on finding out the right option to drill through aluminum you have to be aware of the dangers surrounding it.

You have to understand that it takes only small and tiny metal fragment to lead to serious eye injury. Hence, it is important to ensure proper protection of the eyes when drilling metals.

You must not cut corners and choose the best possible safety glasses which will not only protect the eyes but also offer a protection around the sides of the face.

Drilling A Hole Using The Lathethe Mechanics

Always Look For Lubricated Bits

Further it would always be better to look for lubricated bits when it comes to flat metal brackets and other such fixtures and fittings. This is all the more important for drilling holes in steel and iron which is more than 1/8 inches or thicker. You must choose the right cutting fluid like 3 in one lubricating oil. This will go a long way in reducing friction and also prevent excessive heat buildup. This also will go a long way in making drilling that much easy and the bits will also have much longer extended life and durability.

If you are using cast iron, brass or easier to drill metals like aluminum, brass or cast iron, you would not require too much of lubrication.

Importance Of Making A Dimple

Drill bits have the habit of wandering as you make the first drilling. This could lead to drilling happening in the wrong place. To prevent this you must understand the need for marking and measuring where you would like to make the hole. You could then make use of a center punch and hammer and this will create a small dimple. This will also gives the tip of your drill that much space and place to enter in and you start drilling.

Clamps Could Prevent Stitches

It would not be advisable to hold a piece of metal in one hand as you try to drill with the help of the other. Hence, you must ensure that the metal or surface being drilled must be fixed steadily and using a quality clamp is the best way forward.

Apart from the above there are quite a few other things which you must bear in mind when it comes to choosing the right clamping bit and the right surface also.

Description

This section is from the book 'Machine Shop Work', by Frederick W. Turner, Oscar E. Perrigo, Howard P. Fairfield. Also available from Amazon: Machine shop work.

A piece to be turned is supported on the two centers of the lathe. In order that this may be done, it is prepared by drilling and countersinking a hole in each end. This is called centering the work. The countersunk hole should have the same angle as the lathe center upon which it is to run. The hole should be drilled deep enough so that the point of the lathe center may not strike. The shape of the hole is shown in Fig. 133. The generally accepted standard angle is 60 degrees. The effect of using a 60-degree hole on a 90-degree center is shown in Fig. 134. The result of such an application is that the bearing will be concentrated on a line AB, causing rapid wear of the outer end of the hole, and a cutting of the dead center.

Fig. 133. Hole and Center of Correct • Angle for Centering Work.

Fig. 134. Effect of Using Different Angled Hole and Center.

The size of center holes varies with the weight of the work and the character of the operation. Heavy work and rough turning require large center holes, while small work and fine turning can be done without countersinking deeply. As bearing surfaces in cast iron must be large to be satisfactory, center holes in cast iron are likely to give trouble by unequal and rapid wear. When heavy turned work in cast iron must be very accurate, it is well to drill a hole in each end, drive in a plug of Wrought iron or mild steel, and form the center holes in the plugs thus driven.

When the piece to be turned has been put in place, the dead center should be oiled and screwed up into position. It should be tightened so that there is no lost motion, and yet allow the work to rotate freely.

Chuck Method

The turning of shafts and bars is not, however, the only kind of work to be done on a lathe. Pieces can be turned that are thin, that have holes through the center, or which are so shaped that they cannot be held upon the centers. In such cases it becomes necessary to hold the work firmly without distortion. This may be done by use of the lathe chuck.

Drilling A Hole Using The Lathethe Mechanical

Fig. 135. Work Clamped to Faceplate.

Faceplate Method

Still another method of holding a piece to be worked is that shown in Fig. 135. The piece is clamped to the faceplate. When this is done, there should be a bearing on the faceplate immediately beneath the clamping strap. For example, consider Fig. 136. Suppose a disc having four feet on one side is to be faced off on the front. The clamps should be placed directly over the feet, as in B. If they are placed between the feet at EE, the work will be sprung out of shape, as shown by the dotted lines in A. Then, when the tool has done its work, the shape of the piece, while bolted to the faceplate, will be as shown in C. As soon as the pressure of the straps is removed, the elasticity of the metal will cause the piece to assume the convex form shown in D; whereas, if the straps had been placed as shown in B, no distortion would have been produced.

Fig. 136. Proper and Improper Method of Clamping Work.

An angle iron may be clamped on a faceplate, as shown in Fig. 137, presenting a surface parallel to the lathe axis, to which work may be attached. The angle irons may, of course, be at any angle to the faceplate, but 90 degrees is the one most commonly used. When work is held in this manner, it is desirable to counterbalance it, as is also shown in Fig. 137,

Fig. 137. Angle Iron Clamped to Faceplate and Counterbalanced.

Continue to:

- prev: Cooling the Tools

- next: Adjusting Pieces to Center on Faceplate